With the rapid sci-tech progress in recent years, aerospace and automobile industries have placed higher requirements on the performance indicators of power electronic devices and the ability of the devices to work in harsh working environments, so a new generation of power electronic devices are expected to have excellent attributes, e.g. higher voltage resistance, higher switching speed, lower loss and high temperature resistance and can function well in harsh working environments like high temperature and strong irradiation.

After the development for decades, the technology of traditional silicon-based semiconductor devices has become mature, and the performance of silicon-based devices has come to their physical limits, which means they are not up to the applications with high temperature, high pressure and high frequency, etc. Compared with silicon materials, silicon carbide (SiC) materials have a wider band gap width (3 times that of silicon), a higher critical breakdown electric field (10 times that of silicon), a higher thermal conductivity (3 times that of silicon), a higher intrinsic failure temperature (over 500 °C), more stable chemical properties and better irradiation resistance. SiC has these superior physical and electrical properties, so the power devices based on SiC materials are ideal for the applications with high temperature, high pressure, high frequency, and strong radiation.

However, the current actual SiC MOSFET devices are confronted with serious challenges, such as total dose effects and single particle effects, poor radiation resistance and low stability, so they cannot satisfy the application requirements of aerospace avionics. Therefore, many problems are to be tackled in the research of the radiation effects of SiC MOSFET devices; for example, there lacks theoretical research on device radiation effects and failure mechanism, the test methods of device radiation effects and the evaluation methods of radiation resistance need to be improved, and the radiation hardening technology based on the innovative design of device structures and manufacturing improvement methods needs to be studied.

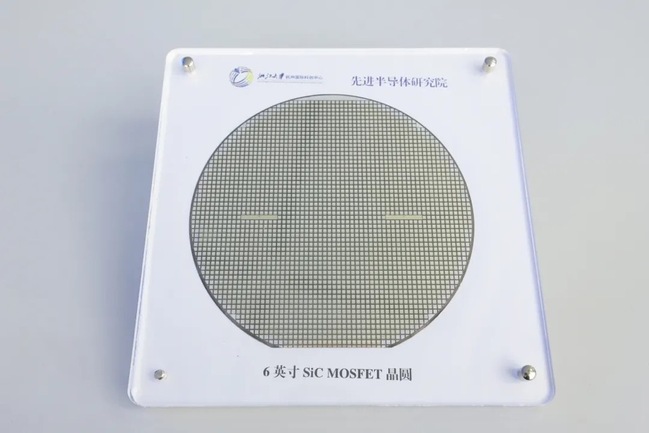

The major participant of the project, REN Na, a young researcher in Power Chip Research Laboratory of Advanced Semiconductor Research Institute at ZJU-Hangzhou Global Scientific and Technological Innovation Center, will make full use of the research foundation and technical reserves of the team in silicon carbide power MOSFET devices, as well as the first-class experimental facilities and research capacity of the Center to cooperate with Yangtze Delta Region Institute of Tsinghua University, Zhejiang for the research and technological innovation on the “bottlenecks” in radiation resistance of silicon carbide power MOSFET so as to reveal the special radiation effect mechanism of silicon carbide MOSFET, break through traditional radiation hardening methods in silicon-based devices, propose a variety of new and efficient combinations of hardening technologies, implement all-round radiation resistance hardening for silicon carbide power MOSFET devices from multiple angles, change the inefficient single-point trial and error methods of the traditional hardening technologies of power MOSFET devices, improve the corresponding technical design rules, guide and develop the radiation resistant power MOSFET products in series.